Automatic Back Order Fill Algorithm Matrix - SET 30

Choosing open pallet or roll receipt when there are Multiple Receipts

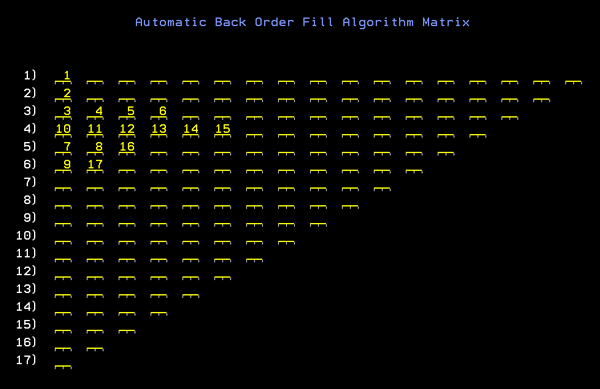

There are 17 available back order fill algorithms. The Algorithm Matrix Screen allows you to set up exactly how the algorithms are sequenced. There are up to 17 spaces going across and 17 spaces down the screen. Each of the 17 lines going down represents an entire iteration of reading all back orders eligible to be filled. In effect, the file of back orders to fill is read up to a maximum of 17 times. Actually the file is only read as many times as you have lines on the Algorithm Matrix with at least one algorithm listed. The 17 algorithms are represented by the numbers 1 through 17. The 17 lines going across represent algorithms processed for each back order before reading the next back ordered line in the file. Therefore, you should read the example above as follows:

- Process algorithm 1 against each back order in the file.

- Process algorithm 2 against each back order in the file

- Process the first back order in the file with algorithm 3, then 4, 5 and 6 before reading the next back order and processing those four algorithms, and so on.

- Process the first back order in the file with algorithm 10, then 11, 12, 13, 14, and 15 before reading the next back order and processing those six algorithms, and so on.

- Process the first back order in the file with algorithm 9 then 17, before reading the next back order and processing those two algorithms, and so on.

The program uses the first algorithm which can successfully fill an order and then stops processing it. Therefore, the assumption is you will sequence the algorithms in order of most preferred to least preferred.

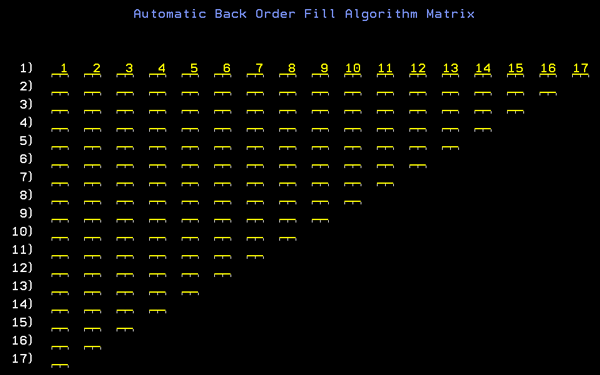

The example below is the most extreme method for favoring customers with the earliest ship or orders dates. This setup favors earliest dates because the back orders are sequenced by your choice of ship date or order date and this setup causes the program to try all of the 17 algorithms against the first (earliest) back order before trying to fill the next back order.

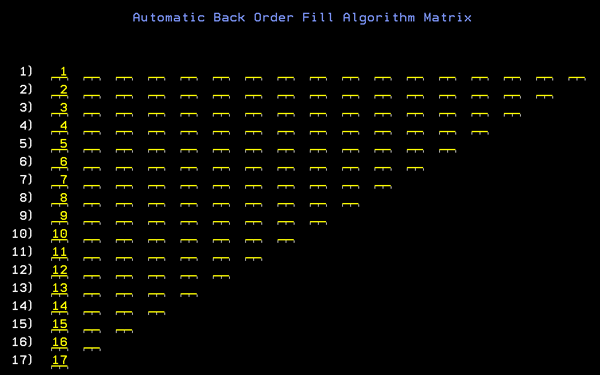

The next example is the most extreme method for favoring optimum use of the received inventory. This setup favors inventory optimization because it tries the most inventory-friendly algorithm for all back orders before it attempts the second algorithm and so on. In general, the algorithms are arranged in most to least inventory-friendly sequence.

The challenge in determining the optimum algorithm matrix, is in balancing two priorities: the optimization of the received inventory, and servicing customers based upon their order or ship dates. When setting up the matrix, you may include the same algorithm number twice, and you may omit algorithms. However, it is recommended to simply include all algorithms one time each, in the desired sequence.

The seventeen automatic back order fill algorithms are described in the table below.

| Algorithm | Definition |

| Algorithm 1 | Special Orders. Only match a special order against a receipt with that exact item number, warehouse, and special order lot number. |

| Algorithm 2 | A single receipt number with exact quantity of back order. Receipt warehouse=back order Header warehouse. |

| Algorithm 3 | Any two single receipt/line numbers that total exact quantity of back order. Receipt warehouse=back order Header warehouse. |

| Algorithm 4 | Any three single receipt/line numbers that total exact quantity of back order. Receipt warehouse=back order Header warehouse |

| Algorithm 5 | Any four single receipt/line numbers that total exact quantity of back order. Receipt warehouse=back order Header warehouse. |

| Algorithm 6 | A single receipt/line number with >exact quantity of back order, but would not leave a different in stock that is =< the remnant quantity in the item file. Receipt warehouse=back order Header warehouse. |

| Algorithm 7 | Any number of receipt/line numbers with a total that is => the exact quantity of back order, but would not leave a difference. in stock that is =< the remnant quantity in item file. Receipt warehouse=back order Header warehouse. |

| Algorithm 8 | A single receipt/line number with > exact quantity of back order regardless of remnant consideration. Receipt warehouse=back order Header warehouse. |

| Algorithm 9 | Any number of receipt/line numbers with a total => exact back order quantity, regardless of remnant consideration. Receipt warehouse=back order Header warehouse. |

| Algorithm 10 | Same scenario as algorithm #2 where receipt warehouse is not the same as back order Header warehouse. |

| Algorithm 11 | Same scenario as algorithm #3 where receipt warehouse is not the same as back order Header warehouse. |

| Algorithm 12 | Same scenario as algorithm #4 where receipt warehouse is not the same as back order Header warehouse. |

| Algorithm 13 | Same scenario as algorithm #5 where receipt warehouse is not the same as back order Header warehouse. |

| Algorithm 14 | Same scenario as algorithm #6 where receipt warehouse is not the same as back order Header warehouse. |

| Algorithm 15 | Same scenario as algorithm #7 where receipt warehouse is not the same as back order Header warehouse. |

| Algorithm 16 | Same scenario as algorithm #8 where receipt warehouse is not the same as back order Header warehouse. |

| Algorithm 17 | Same scenario as algorithm #9 where receipt warehouse is not the same as back order Header warehouse. |

All algorithms that are allowed to mix more than one receipt are first verified against the ISO table for the respective item. The ISO rules for mixing shades, serial numbers, etc., are applied to automatic back fill. You must have ISO tables established in order for you to obtain the optimum results from Automatic Back Order Fill.

Setup Back Order Fill Defaults for each user, by pressing F9 on the Back Order Fill Program on the Pre-Receipts And Back Order Fill Menu. This allows you to specify the warehouses each user is allowed to process within the back order fill process.

Choosing open pallet or roll receipt when there are Multiple Receipts

Auto Back Order Fill uses 17 algorithms to fill back orders based on user setup. However, when there are multiple receipts, each of which can fill a back order, there is no setting that causes the program to choose an open pallet or roll over a closed one (ie: a pallet or roll that was already selected by the auto-fill to fill a previous back order in the same run).

In August of 2015, functionality was added to algorithms 6, 8, 14, and 16, that allows them to choose an open pallet or roll over a closed one, when all else is equal.

Here's how it works:

- if there are multiple receipts that can fill a back order, the program uses the smallest previously opened (used) receipt.

- if there are multiple receipts that can fill a back order, but none were previously opened (used), the program uses the smallest receipt (as long as it can fill the back order).

This concept works for Rolled Goods as well as Serialized items.

If the ISO setting OK to mix serial#s (on the Rules screen) is set to "N", this functionality might not work as described, as the individual serial#s are done as separate runs within the program.

Associated Files

- Fill Back Orders - INB 4

- Post Receipts, Update Back Orders, and Process Pick Lists - INB 5

- Auto Back Order Fill Warehouse Settings - SET 35

- Test Automatic Back Order Fill - SYS 914

- Purge Unprocessed Pending lines with no allocations by Date (back order) - SYS 925

- Back Order ETA Date Report and Update - PUR 19

- List Back Orders That Can Be Filled From Available Local Stock (ROO 17)